When he met Bill Gates at a conference in May 2010, UNC pharmacology professor Joseph DeSimone knew how to get his attention.

He told Gates that his company, Liquidia Technologies, was producing medicine and vaccines using the same manufacturing techniques as Microsoft.

His pitch worked.

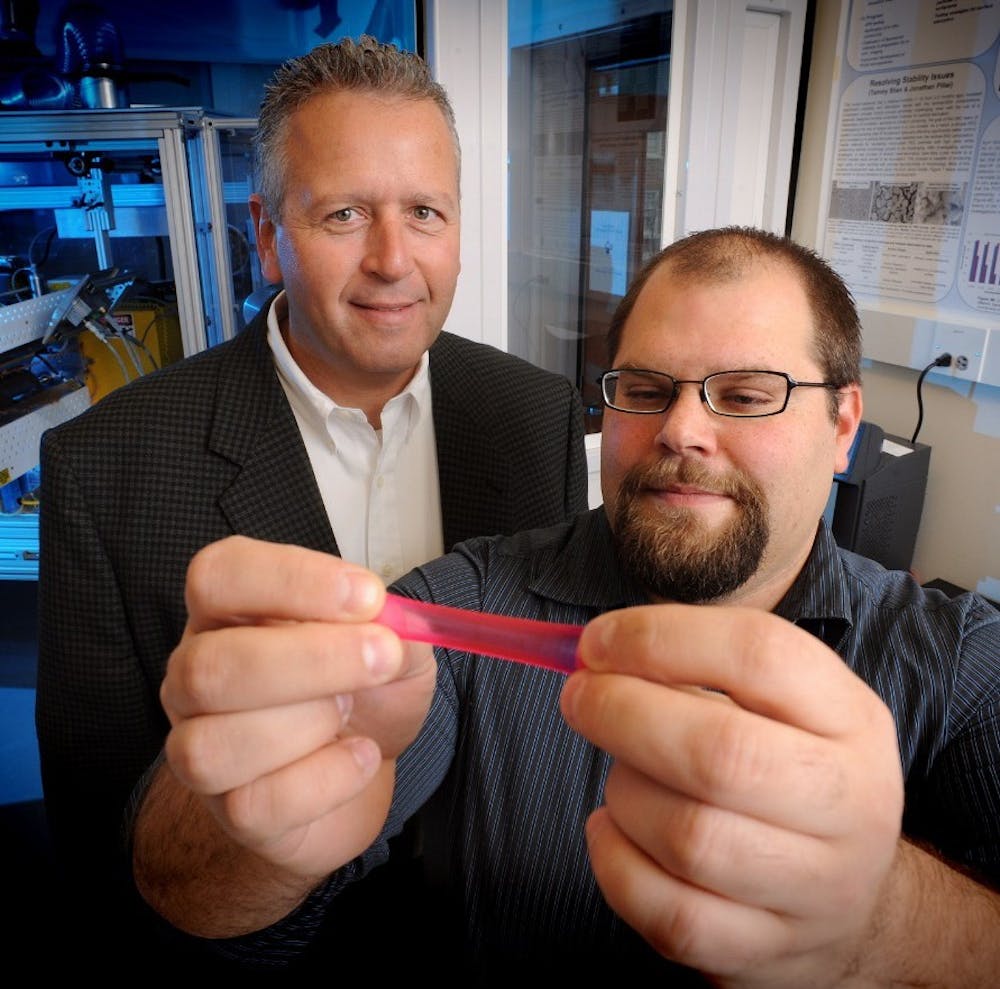

On March 4, Liquidia Technologies announced it had received a $10 million program-related investment from the Bill and Melinda Gates Foundation for the development of Particle Replication in Non-wetting Templates (PRINT) technology, which could make research and development of medicines more efficient.

PRINT is a form of top-down nanotechnology, which DeSimone said had been previously non-existent in similar projects. It creates nanoparticles uniform in size, shape and chemical composition.

Chemists typically use bottom-up nanotechnology to make particles, whereas electrical engineers typically use top-down nanotechnology to create patterns on surfaces.

“We bridged two very different fields and techniques …. No one’s done that before,” he said.

DeSimone said the idea came to him in 2004 when he noted the need for a more sophisticated manufacturing process which could create physically uniform particles.

Liquidia then started making what DeSimone describes as “ice cube trays on a nanoscale template.”