“We’ve been getting feedback from physicians, clinicians, nurses and doctors in the field about what they want to see in a face shield,” Langley said. “So we took something that sort of the University of Wisconsin made, and we modified that to suit our end user here.”

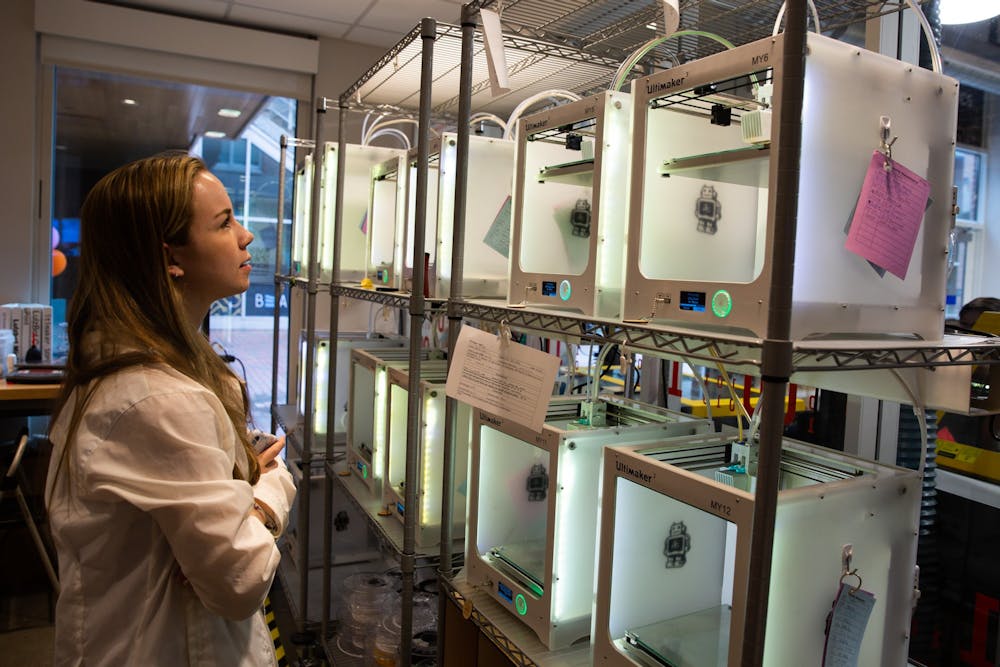

Demitra Canoutas, a third-year medical student, said BeAM is working on producing two models of the shields. The first can be hand-assembled using a foam band with elastic, and will be produced early next week. The second version of the shields will take a bit longer to produce, she said, but will be 3D-printed.

“Those 3D-printed ones will be able to snap together, so they won’t require as much assembly, and then they can be disassembled and sterilized for reuse,” Canoutas said. "However, Langley said that even the hand-built shields can be reused and sanitized if necessary.

Canoutas said BeAM is still sourcing materials, but has shipments coming in.

“Our goal is to make 1,000 shields by the end of next week and scale up to 10,000 from there,” she said.

Langley said these shields will not be the primary source of defense for health care workers.

“The health care system would not use these unless they absolutely had to. They would use all of their FDA-approved materials and PPE," Langley said. "It was only if they burned through those and had nothing left they would reach for these."

Canoutas said next week, BeAM will start bringing in volunteers to make the masks. Over 100 medical students have volunteered to help with the production effort, and will soon come in shifts to assemble and distribute the shields.

“Since we’re not able to be in clinic right now, this is a great way for us to hopefully make a contribution to UNC Health during COVID,” Canoutas said.

Langley said BeAM will also be reaching out to people on its email list to collect volunteers based on their feedback to a survey.

“We're looking for people that are honest about their feedback and that are practicing true social distancing and CMC hygiene guidelines," he said.

Langley said UNC is not working in a vacuum. Institutions across the state are collaborating and putting forth a cohesive effort to assist the health care systems.

To get the day's news and headlines in your inbox each morning, sign up for our email newsletters.

“I have to give credit back to some of the leaders here at UNC, because they’re actually working lockstep with Duke, N.C. State, UNC-Charlotte and other systems so that we’re not reinventing wheels in our respective silos,” Langley said. “There’s some terrific communication going on, and we’re getting new information emailed every day, and we’re in touch with private industry.”

university@dailytarheel.com